Success Stories

Cold Chain Monitoring brings down compliance risks by 85%

Industries

Logistics and Supply Chain Management

Technologies

Industrial-grade sensors, Azure IoT Edge, Raspberry Pi, Power BI

Cold Chain Monitoring brings down compliance risks by 85%

Helping businesses comply with regulations while deploying smart technological solutions is at the core of what we do here at arieotech. Our solutions are backed by technological expertise but always driven toward the best possible outcome for clients, given their specific needs and challenges. This is what we were able to achieve in our work with a cold chain logistics company.

Challenge

A leading cold chain logistics company was serving over 100 clients across the food, healthcare, FMCG, and retail sectors. Their ambient and temperature-controlled infrastructure spanned warehousing and distribution and included a fleet of 500+ trucks connecting over 15 cities. Such a scale of operations, however, demanded real-time visibility of critical parameters such as humidity, vibration, and light exposure to ensure the best service.

Keeping manual track of these crucial indicators—and the lack of a unified sensor network—meant that data was fragmented, and system-wide oversight was not possible. This led to delays in course correction, spoiled goods, and high losses. The client wanted a solution that would not only monitor these parameters in real-time but also make them visible and flag any issues requiring urgent attention.

Solution

arieotech delivered a unified, intelligent monitoring solution that enhanced the client’s cold chain operations. We began by standardizing temperature and humidity sensors across all sites, ensuring reliable data collection. To eliminate delays, we implemented edge devices like Azure IoT Edge and Raspberry Pi, enabling real-time alerts and anomaly detection at the source.

We then built a cloud-based pipeline using Azure IoT Hub, Stream Analytics, and Power BI, giving teams centralized, real-time visibility across warehouses and fleets. With built-in traceability and audit-ready logs, the solution not only accelerated response times but also positioned the client ahead of regulatory demands.

Impact

Latency cut by 90%

Compliance risk down by 85%

95% faster alerts

At arieotech, we believe technology is a catalyst for meaningful business transformation. As a forward-thinking technology solutions partner, we help organizations unlock the full potential of their data, modernize operations, and drive measurable outcomes. In our recent work with a cold chain logistics company, we were able to do just that.

Lack of Accurate Monitoring Across the Cold Chain

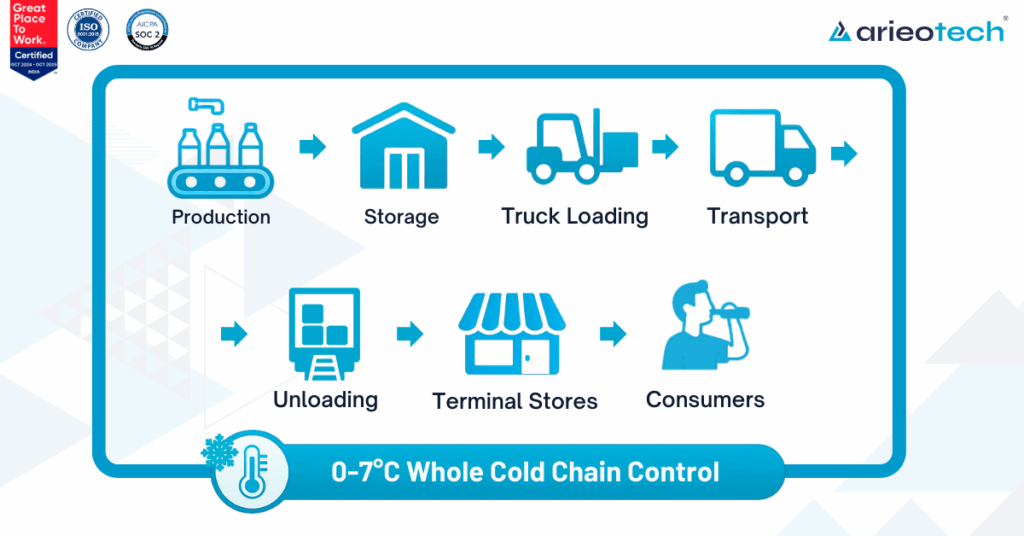

The company had a wide roster of food, healthcare, FMCG, and retail clients. They handled goods and products from source to consumption point. This meant they offered ambient, temperature-controlled warehousing and distribution, connecting manufacturers, processors, distributors, retailers, and end consumers.

With a fleet of 500+ trucks across 15+ cities, they were struggling to accurately track sensitive data across locations. This included critical parameters such as humidity, vibration, and light exposure—non-compliance with which could lead to serious regulatory implications. The lack of a unified sensor network resulted in fragmented data. With no efficient way to monitor these parameters, the company faced compliance risks and frequent losses due to delayed interventions and compromised goods.

The client wanted a solution that would not only monitor these parameters in real-time but also make them visible and flag issues requiring immediate attention.

Engineering Real-Time Intelligence at Scale

To restore visibility, speed, and confidence across the client’s cold chain operations, arieotech delivered a comprehensive, future-ready solution. We began by deploying a standardized network of industrial-grade temperature and humidity sensors (Sensitech, Monnit) across all facilities. This ensured data was reliably collected at every site, guaranteeing consistency and accuracy.

Recognizing that speed is critical in cold chain logistics, we integrated edge devices such as Azure IoT Edge and Raspberry Pi to enable real-time data processing right where it mattered. This allowed temperature anomalies to be flagged instantly.

But we didn’t stop there. We built a secure, cloud-connected pipeline using Azure IoT Hub, Stream Analytics, and Power BI, giving the client a unified dashboard view across geographies. From warehouse floors to fleet operations, decision-makers could now monitor live temperature conditions, track deviations, and act faster than ever before.

Setting New Standards for Compliance and Visibility

With audit-ready data logging and traceability baked into the architecture, the solution didn’t just meet regulatory expectations—it exceeded them. In short, arieotech transformed a fragmented monitoring system into a real-time, intelligent, and compliant cold chain infrastructure.

At arieotech, putting technology to the best business use is our core driving force. With our expertise and commitment to results, we were able to bring about unparalleled efficiency while addressing a critical challenge of the sector. Our solution was designed specifically for this sector and this problem.

If you’re curious about how we can do this for you, contact us now.